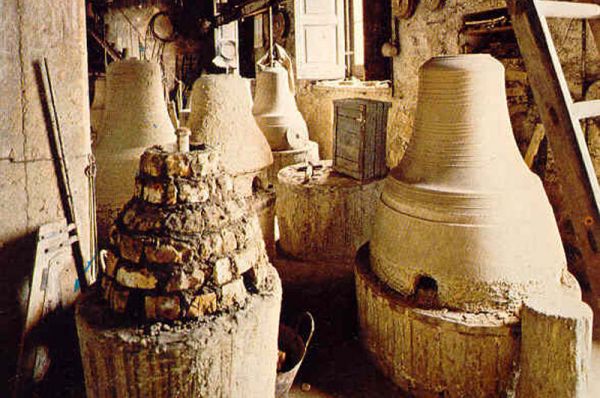

Ancient Working

The phases leading up to the birth of Bell requires a careful and patient work but mainly experience and passion.In 1700 bells had taken a well-defined shape, very similar to the present one, however the disproportion between diameter and height persisted and the bells continued to have a streamlined appearance. In order to achieve the perfection it was necessary to have the sound of each bell well defined and reproducible, for this reason it was defined a reference scale indicating the proportions between thickness, weight, width and height, to use in order to obtain the desired sound. Marinelli Foundry use today the same techniques and materials used by masters of the middle ages and Renaissance. No technology has accelerated the processing cycle that, as originally was, can take from two weeks to several months.

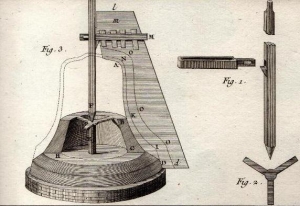

Components of a Bell

Phases of Work

Preparation of the mold

The first task that an artisan has to accomplish when he or her begin to work on a new bell, is the construction of a model of the internal shape of the bell. This is done cutting and modelling a piece of walnut wood into a shape that matches the internal outline of the bell. Having a model, the artisan, can begin to construct a bricks structure of the internal bell, the bell’s Soul.

The first task that an artisan has to accomplish when he or her begin to work on a new bell, is the construction of a model of the internal shape of the bell. This is done cutting and modelling a piece of walnut wood into a shape that matches the internal outline of the bell. Having a model, the artisan, can begin to construct a bricks structure of the internal bell, the bell’s Soul.

Onto the soul, several layers of a special kind of clay are spread until the thickness reach the one desired for the final bronze bell and a smooth surface is obtained. Now, using wax, which is a more workable material, all the desired dedication or pictures are applied and then covered again with another portion of clay. A False bell has been created.

The last phase before the actual bronze casting, is the preparation of the external part of the mold: the mantle. It is obtained overlapping several layers of clay and, once the clay is dry, it will correspond perfectly to the external shape of the bell. The very last task to accomplish is to remove the false bell; it was useful only to shape the external part of the mold, so it can now be broken in order to obtain a cavity that perfectly matches the shape of the final bell. Everything is ready for the bronze casting.

Fusion

The bronze (alloy composed of 78 part of copper and 22 of tin) is kept in molten state into a huge oven at about 1150°C. The mold is placed firmly into the casting ditch, just below the oven, waiting for the bronze flow. Traditionally, bells are considered sacred, so each of them has to be blessed. For this reason the opening of the oven that initiate the casting is made praying ”Santa Maria!”.

Conclusive phase

Once the bronze is cold, the bell is taken out from the ditch, it is freed from the mold and it is cleaned and polished. The bell is almost ready, last things to do are an acoustic test and the application of a clapper and the electronic system for the automatic sound.

After a long work the bell is born and it is ready to begin its journey!

Images of Foundry